Special Note:

●The load rating of the following sliding wheel series products is the maximum load that the sliding wheel assembly can bear when the force is a steel surface, and the most important thing is the material of the force surface if you want to move the load safely and reliably. Tile or fragile force surface is not suitable for sliding wheel work, when working on concrete or apron force surface, the load capacity of sliding wheel will be limited (depending on the design pressure of force surface and surface flatness).

●It is recommended to lay a steel plate with a thickness of 10mm or more on the stressed surface, and the pulling force of the sliding wheel is generally 4%-7% of the actual load (depending on the flatness of the stressed surface). When working on the slope, some safety precautions must be taken to avoid runaway sliding wheels and load tipping.

●When choosing sliding wheels, consider whether the load weight is evenly distributed to ensure that the force of a single sliding wheel unit is within its rated load capacity, and if necessary, the number of sliding wheel units can be partially increased.

| |||||

| MODLE | SF10 | SF20 | SF25 | SF30 | SF60 |

| Rated load capacity(T) | 1 | 2 | 2.5 | 3 | 6 |

| Number of wheels | 4 | 8 | 2 | 4 | 6 |

| Wheel specification (Nylon)(mm) | Ф100*35 | Ф100*35 | Ф85*90 | Ф85*85 | Ф85*85 |

| Load surface size(L×W)(mm) | 330*195 | 330*195 | 220*94 | 330*195 | 250*170 |

| Product dimensions (L×W×H)(mm) | 330*220*120 | 330*220*120 | 310*100*105 | 330*300*120 | 260*230*105 |

| Net weight(KG) | 7 | 8 | 4 | 9.5 | 12 |

| ●Use with pry bar or jack. Can be used to move heavy loads ●Wear-resistant rubber surface prevents the load from sliding and effectively protects the load surface | |||||

|  |  |  |  |

| ET3A+ET3B total load capacity 6T | ET6A+ET6B total load capacity 12T | ET9A+ET9B total load capacity 18T | ET12A+ET12B total load capacity 24T | ET20A+ET20B total load capacity 40T |

| American style sliding wheel | |||||

| MODLE | ET3A | ET6A | ET9A | ET12A | SF20A |

| Rated load capacity(T) | 3 | 6 | 9 | 12 | 20 |

| Height of load surface from the ground(mm) | 110 | 110 | 110 | 110 | 110 |

| Number of wheels | 4 | 8 | 12 | 16 | 16 |

| Wheel specification (Rubber)(mm) | Ф85*85 | Ф85*85 | Ф85*85 | Ф85*85 | Ф85*85 |

| Diameter of rotatable support surface(mm) | Ф170 | Ф170 | Ф170 | Ф170 | Ф250 |

| Overall Dimension(L×W)(mm) | 270*230 | 610*520 | 815*600 | 900*600 | 1090*730 |

| Handle length(mm) | 960 | 1080 | 1080 | 1080 | 1620 |

| Net weight(KG) | 15 | 45 | 56 | 73 | 188 |

| ●Swedish original imported high-strength heavy-duty wheels, smooth moving and durable. ●The supporting surface of A type sliding wheel is steerable, the supporting surface of B type sliding wheel is fixed flat, and the length of connecting rod of B type sliding wheel is adjustable. ●A and B type are used together | |||||

| MODLE | ET3B | ET6B | ET9B | ET12B | SF20B |

| Rated load capacity(T) | 3 | 6 | 9 | 12 | 20 |

| Height of load surface from the ground(mm) | 110 | 110 | 110 | 110 | 110 |

| Number of wheels | 4 | 8 | 12 | 16 | 16 |

| Wheel specification (Rubber)(mm) | Ф85*85 | Ф85*85 | Ф85*85 | Ф85*85 | Ф140*85 |

| Support surface size(L×W)(mm) | 150*150 | 220*200 | 180*170 | 220*220 | 280*220 |

| Handle length(mm) | 960 | 1080 | 1080 | 1080 | 1620 |

| Net weight(KG) | 16 | 32 | 34 | 45 | 95 |

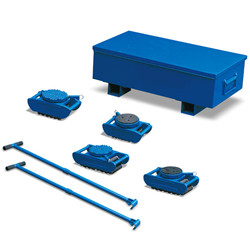

| European type sliding wheel (tank car) kit | ||||

| Combination model | Rated load capacity(T) | Product Details | Net weight(KG) |

| HRS-15-SVP | 15 | Four SVP3.75 tank cars, two tie rods, one tool box | 80 | |

| HRS-15-SVD | 15 | Four SVD3.75 tank cars, two tie rods, one tool box | 84 | |

| HRS-40-SVP | 40 | Four SVP10 tank cars, two tie rods, one tool box | 88 | |

| HRS-40-SVD | 40 | Four SVD10 tank cars, two tie rods, one tool box | 92 | |

| HRS-60-SVP | 60 | Four SVP15 tank cars, two tie rods, one tool box | 108 | |

| HRS-60-SVD | 60 | Four SVD15 tank cars, two tie rods, one tool box | 112 | |

| European style sliding wheel (tank car) unit | ||||||

●SVD series is steel cam surface, rotatable and positionable ●SVP series is rubber cushion surface, rotatable and positionable |  | |||||

| MODEL | Rated load capacity(T) | Wheel specification (Rubber)(mm) | Top surface type | Number of wheels | Overall Dimension(mm) | Net weight(KG) |

| AQ-R10 | 3.75 | Ф24*84 | Rubber pad | 14 | 267*146*127 | 15 |

| AQ-R20 | 10 | Ф24*84 | Rubber pad | 14 | 267*146*133 | 17 |

| AQ-R30 | 15 | Ф30*102 | Rubber pad | 16 | 324*165*130 | 21 |

| AQ-S10 | 3.75 | Ф24*84 | Rigid convex tooth surface | 14 | 267*146*121 | 15 |

| AQ-S20 | 10 | Ф24*84 | Rigid convex tooth surface | 14 | 267*146*133 | 16 |

| AQ-S30 | 15 | Ф30*102 | Rigid convex tooth surface | 16 | 324*165*130 | 21 |

< /BR>1 < /BR>

Why Choose Us:

1. You can get the perfect material according to your requirement at the least possible price.

2. We also offer Reworks, FOB, CFR, CIF, and door to door delivery prices. We suggest you to do deal for shipping which will be quite economical.

3. The materials we provide are completely verifiable, right from raw material test certificate to the final dimensional statement.(Reports will show on requirement)

4. e guarantee to give a response within 24hours(usually in the same hour)

5. You can get stock alternatives, mill deliveries with minimizing manufacturing time.

6. We are fully dedicated to our customers. If it will not possible to meet your requirements after examining all options, we will not mislead you by making false promises which will create good customer relations.

Quality Assurance(including both Destructive and Non-Destructive)

1. Visual Dimension Test

2. Mechanical examining like tensile, Elongation and reduction of area.

3. Impact analysis

4. Chemical examination analysis

5. Hardness test

6. Pitting protection test

7. Penetrant Test

8. Intergranular Corrosion Testing

9. Roughness Testing

10. Metallography Experimental Test

Product search